Improved A/C Efficiency with Oil-less Compressor and Variable-Speed Operation

Most of the air conditioning (A/C) compressor pumps on the residential market today are scroll compressors and piston compressors. Both types of compressors require oil to be added to the refrigerant to act as a lubricant and both types of compressors operate at a single prescribed RPM, modulating their cooling capacity by cycling on and off. A new compressor has been designed, differing from scroll and piston compressors in two significant ways: 1) It can operate using a pure refrigerant without adding any lubricating oil, increasing heat transfer and thermodynamic efficiency, and 2) It can operate continuously with variable RPMs, adjusting the cycle to meet ideal operating conditions. The combination of these two design features results in increased performance of the A/C cycle, significantly reducing the overall electrical consumption and cost of the system.

Refrigeration Cycle

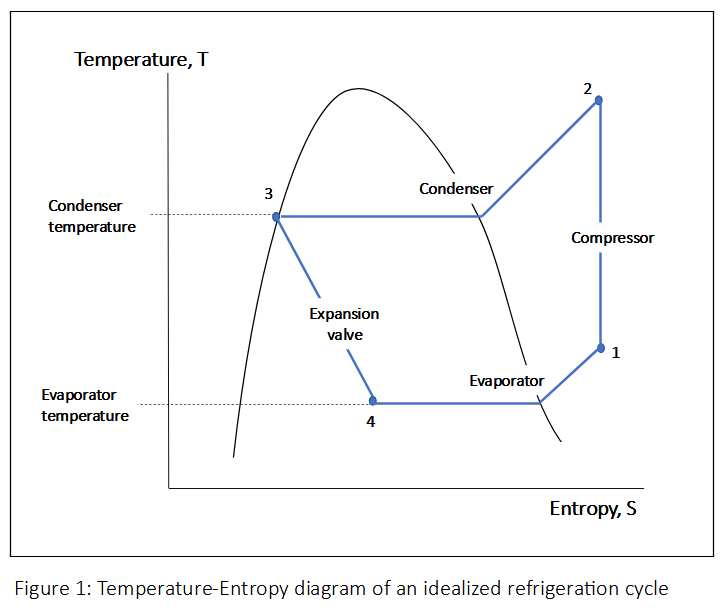

In an A/C system, a refrigerant circulates through a refrigeration cycle, absorbing heat from the interior of a building and expelling heat to ambient air exterior of the building. An idealized refrigeration cycle is shown in a T-S diagram in Figure 1, including a compressor, a condenser, an expansion valve, and an evaporator. The compressor uses electrical work to compress the refrigerant from a low-pressure, low-temperature gas (State 1) to a high-pressure, high-temperature gas (State 2). The required work input increases as the exit temperature and the corresponding compressor pressure ratio (high pressure to low pressure) increase. Next, the refrigerant enters the high-pressure condenser and changes phase from gas (State 2) to liquid (State 3) as heat flows from the interior of the condenser, conducted through copper tubing, and rejected to the surroundings outside of the condenser, the exterior of the building. The temperature difference between the condenser and the surroundings must be large enough to achieve the required heat transfer rate for cycle operation. However, a condenser that operates with a high rate of heat conduction requires a relatively small temperature difference between the condenser and surroundings, corresponding to a lower condenser pressure and reduced compressor work.

Next, an expansion valve transforms the high-pressure liquid at the condenser exit (State 3) to a low-pressure liquid-vapor mixture at the evaporator inlet (State 4) located in the interior of the building where cooling is desired. Heat from the building flows to the cold evaporator, conducted through the copper tubing walls of the evaporator, and absorbed by the refrigerant. The result is a low-pressure gas at the evaporator exit (State 1), completing the thermodynamic cycle. The temperature difference between the cold evaporator and its surroundings must be large enough to achieve the desired heat transfer rate. An evaporator designed to operate with a high conductive heat transfer rate, requires only a small temperature difference, allowing a relatively warmer evaporator operating temperature. A warmer operating temperature for the evaporator still below the temperature of the building) corresponds to a higher evaporator pressure, reducing the compressor pressure ratio and reducing the work input for the cycle.

Oil-less Compressor

Existing compressors in A/C systems have metal-on-metal contact points and require a lubricating oil during operation. The concentration of oil in the refrigerant is estimated in the range of 10-20% (1). When oil is added to the refrigerant, it circulates throughout the entire A/C system. As a result, the interior walls of the copper coils in both the condenser and evaporator become coated with a thin layer of oil. This layer of oil becomes an additional barrier for the heat to pass through, slowing the rate of conduction. That is, heat must now be conducted through not only the copper tubing of the condenser and evaporator but must also pass through an additional layer of oil. Further, when looking at the thermal conductivity (k) of copper at 413 W/mK and oil at ≈ 0.15 W/mK, we can see that the rate of conductivity for copper is 2733 times faster than oil (413/0.15) = 2733. Although the layer of oil may be extremely thin, this additional layer of low-conductivity oil greatly slows the rate of heat flow through both the condenser and evaporator. This low conduction rate requires large temperature differences, relative to their surroundings, for both the condenser and evaporator to achieve the necessary heat transfer rate.

The presence of oil in the system is also detrimental to the compressor efficiency, acting as a liquid heat sink at the expense of the refrigerant. The thermodynamic properties of the oil-refrigerant mixture are less desirable than those of a pure refrigerant, with an increase in entropy due to the oil effects that lower the efficiency of the refrigeration components. Oil also acts as a heat sink in the condenser. Here, the latent heat from the refrigerant, as it condenses from a gas to a liquid, along with the additional heat from the high temperature oil, must exit the condenser. As a result, both the heat energy from the condensing refrigerant and the oil need to pass through the walls of the condenser, thereby increasing the required temperature difference between the condenser and surroundings. Again, there is an increase in work required by the compressor and a reduction in the coefficient of performance (COP).

The introduction of a new, oil-less compressor in the A/C system will eliminate the detrimental effects that oil has on the heat transfer rates of the evaporator and condenser. By improving the conductive heat transfer rates for both the condenser and the evaporator, the system can operate with smaller temperature differences between each component and the relevant surroundings. Allowing the evaporator to operate at a higher temperature and pressure (still colder than the interior of the relevant building space), with a cooler condenser at a lower pressure (still warmer than the exterior atmosphere), reduces the pressure ratio of the compressor. These combined effects significantly reduce the work input and improve the COP of the A/C system. In fact, a numerical study conducted by Li et al. predicted that an oil-less compressor results in a 45% improvement of the COP compared to a compressor with 7% oil concentration (2).

Variable-Speed Operation

In addition to oil-less operation, improved A/C performance can be achieved with a compressor that uses a variable speed to adjust to the ideal cycle parameters for the necessary cooling requirements and surrounding temperatures. Electrical motors that drive the compressors draw more power when they are cycled on and off with a relatively high RPM, compared to continual operation at a reduced RPM. The initial startup of any motor from a dead stop causes a large draw in amperage to get both the motor and A/C system up to operational speed. In contrast, a compressor driven continually by a motor at a lower RPM reduces electrical consumption. Additionally, continual operation of the refrigeration cycle increases the time available for heat conduction to take place for both the condenser and evaporator.

The heat transfer rate through copper tubing in both the evaporator and condenser is described by Fourier's Law of Conduction in equation (1), where q is the heat transfer, k is the thermal conductivity of the material, s is the material thickness, A is the heat transfer area, and dT is the temperature difference over which the heat transfer occurs.

q = (k / s) A dT (1)

For a given evaporator or condenser, the physical size and material of these components are fixed (thickness s, conductivity k, and area A). However, the temperature difference dT, between the interior and exterior of the device will directly affect the heat transfer rate and is determined by the pressures within the evaporator and condenser (as well as the interior building temperature and outdoor ambient temperature). The total amount of heat transfer that occurs depends on the rate of heat transfer, q, and the period of time over which the conduction takes place.

For any refrigeration system to function properly and cool the required space, a set amount of energy must be removed from the space. For example, assume an A/C system has a cooling capacity of 1 ton, using a scroll pump operating at a constant RPM, with a condenser and evaporator that are both designed to operate at exactly 1-ton cooling capacity with a dT of 10˚C. For one hour of continuous operation, the total heat transfer achieved by the evaporator is 1 ton-hour, or 3.5 kW-hours of heat energy removed from the dwelling (note that 1 ton ≈ 3.5 kW). However, when the requirement for cooling is reduced to half (1.75 kW-hours), this traditional system can only operate at the 1-ton capacity and will cycle on and off to reach the desired amount of heat transfer, operating for only 30 minutes each hour while using the same RPM, dT of 10˚C, and cooling rate of 1 ton.

In contrast, a compressor designed to operate continuously with variable RPM could match the 1-ton rate with a dT of 10˚C when high cooling capacity is required but would reduce to 1/2-ton cooling capacity when the cooling demand decreases to half. This lower rate of continuous cooling would be achieved by decreasing the dT to 5˚C for both the condenser and the evaporator. This smaller dT for the condenser and evaporator allows the compressor pressure ratio to decrease and operate at reduced RPM, requiring less work input and increasing the COP of the entire A/C system while avoiding the inefficiencies associated with start-up and shut-down of an on-off cycle.

Conclusion

Current A/C compressors have two major design flaws that lead to inefficiencies: 1) They are unable to modulate the RPM of the motor driving the compressor pump, therefore cooling capacity is adjusted with an on / off / on method, and 2) current A/C compressors also require a lubricant in the form of oil be added to the refrigerant. Both requirements greatly reduce the COP of the entire A/C system. An oil-less A/C compressor that could operate at variable RPMs would greatly increase the efficiency of the A/C system and possibly double the COP, drastically reducing electrical consumption and cost.

References

Karnaz, J. and Seeton, C. (2018). Evaluation of Lubricant Properties and Refrigerant Interaction. International Compressor Engineering Conference. Paper 2639. https://docs.lib.purdue.edu/icec/2639

Li, Z., Shen, H., Liang, K., Chen, X., and Zhu, Z. (2022). A numerical study on the effect of oil lubricant on the heat transfer and efficiency of a vapor compression refrigeration system. International Communications in Heat and Mass Transfer, 134, 106016.

Brian Davis – 8/11/22

Download Word Doc of this PageUnderwing1000 Home